There is now a worldwide awareness of the challenges facing the environment if we continue living as we are, and an increasing demand for lasting, positive change. This has been felt strongly in the world of packaging, where brands are working on environmentally friendly solutions at rapid speed. As we move into the world of packaging as a company, we feel that the first step we must take is to educate ourselves about this issue. We wanted to share some of what we found with you.

Contents

- What is the problem with packaging?

- Recycling Plastic – A Solution?

- How recycling symbols make recycling complicated

- Consumer confusion

- Innovating plastics labelling

- Paper packaging

- Glass packaging

- Glass recycling

- Aluminium packaging

- Fabric bags

- CZ’s measures to reduce pollution

What is the problem with packaging?

Most conversations about packaging and pollution centre around plastic. The problem lies in the fact that we have become used to the ease and efficiency offered by single used plastic while not yet being able to solve its polluting properties, particularly when it comes to plastic pollution of the sea. An estimated 4.8 to 12.7mt of plastic ends up in our oceans per year, killing millions of animals and destroying one of the planet’s major habitats. Once this plastic waste has reached the sea through rivers and from the land, it breaks down into ‘microplastics’ which are ingested by living creatures at all stages of the food chain, including humans. Once this plastic is in the environment it is extremely difficult to get rid of.

The use of single use plastic is rising, particularly in developing countries which do not always have systems in place to dispose of it safely or recycle. In developed countries the challenges are similar, with many not recycling the bulk of their waste and . In fact, only 91% of plastic isn’t recycled. A plastic bottle, one of the most widely used plastic items globally, can take 450 years to decompose.

Covid-19 has increased the amount of plastic pollution, most noticeably with face masks as was reported in Hong Kong where 70 face masks were found in only 100 metres of beach. The picture is similar elsewhere, not only with masks but also plastic packaged hand sanitiser, increased use of single use cups and crockery and latex gloves.

Plastic’s popularity throughout the pandemic is a good example of why we continue to use it despite knowing the associated pollutive impact. It is plastic’s excellent properties as packaging, and as PPE and in medicine, that mean that it is used regardless of the risks. We have had little choice than to use it in a medical content over the past few months, and the mitigated risks of infection seemed to be considered more important than environmental damage during this time.

Despite complications, it is clear then that plastic does have a wide and effective set of advantages. Plastic effecitively reduces food waste by enabling food to last longer. It has brought fresh water to areas of the world where it is not readily available. It is light, meaning its use can reduce overall packaging mass. Plastic is an extremely durable, hygienic, cheap and lightweight, which is what has made it the packaging of choice for so long and why it will take an equally long time to find ways to work with it that are less harmful.

Recycling Plastic – A Solution?

Recycling seems to be a brilliant solution to our plastic pollution problem: converting waste plastic into new, reused material. But it’s not as simple as it sounds.

How recycling symbols make recycling complicated

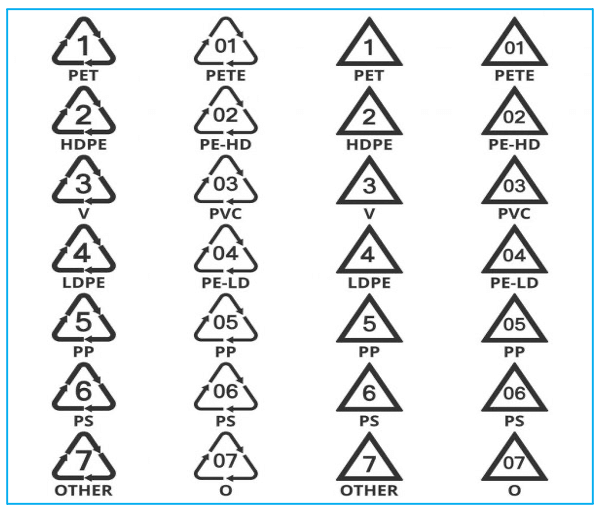

In 1988, the former US Plastics Society introduced a system of Resin Identification Codes (RIC). Since 2008, it’s been administered by the American Society for Testing and Materials (ATSM). Many readers will be familiar with the symbols, but will not necessarily know the meanings behind them.

Resin Identification Codes (RIC) introduced in 1988

The symbols were changed in 2013, from cycling clockwise arrows (called a Mobius loop), to equilateral triangles, although it’s difficult to see how this is an improvement as the Mobius loops are still used in many countries. For food and beverage plastic products, RIC 1, 2, 4, 5 and 6 are the important ones, with the likelihood of 6 being phased out in this sector. By and large, the European countries have used the RIC system, but other countries have adopted greater granularity based on the Chinese model. The RIC system was not designed with consumers in mind and says nothing about how much of each group is actually recycled, only that it could be recycled. It was developed to assist recycling companies and others in identification during the recycling process, as different types of plastics often need to be kept separate for effective recycling.

Consumer Confusion

There have been many attempts to produce an easy-to-understand consumer label, but this has proven difficult. This is partly due to the lack of space on the finished product; it has to compete with other labels on nutrition and ingredients.

Sadly, in some cases, there have been deliberate attempts to exaggerate, deceive, or produce symbols and information that can’t be verified. This is sometimes referred to as ‘greenwashing’. If you’re looking for a good example of how difficult it is to introduce consumers to recycling, look at the European ‘Green Dot’ (Der Grüne Punkt) system, invented in Germany in 1991. The system is used by more than 130,000 companies and encompassed 460 billion packages.

Packaging manufacturers pay a license fee, which is covered under the European ‘Packaging and Packaging Waste Directive – 94/62/EC’. It applies in 26 European countries, with Italy not taking part and, even pre-Brexit, the UK not taking part. The Green Dot scheme was designed to reduce the amount of packaging used by suppliers. In that way, it’s been successful, but it’s relevance to recycling is less. The logo means a company has joined the scheme, not that the package is fully recyclable and there are no associated words with it.

Innovating plastics labelling

Although progress has been made on providing useful information on plastic (and other materials) to consumers, there’s a long way to go. In the next article, we’ll look at how countries have tackled this issue and specifically how the UK has become one of the most innovative.

Our obsession with plastic has also led to innovation that accounts for over 30,000 different types of plastic – each with their own needs in terms of recycling, making a comprehensive and all-inclusive system extremely challenging. Not all plastics are recyclable, for example black plastic, and not all consumers are aware of which types of plastics can and can’t be recycled. This makes recycling complicated and confusing, and also means there isn’t the necessary infrastructure in place to facilitate the rate of recycling that we need to be seeing.

Recycling is also something that heavily relies on exports, which in turn has a negative impact on carbon emissions. Exports account for 67% of recycled plastic in the world, and developing countries are often left with the labour of implementing the processes. They are also more likely to have non-recycled plastic waste exported to them, leading to disease and environmental damage. Malaysia has bared the brunt of the UK’s and other developed countries’ plastic waste, with a large portion of it being dumped there illegally under the guise of ‘recyclable scraps’. Despite the Malaysian government shutting down over 200 recycling factories due to non-compliance with regulations, there is concern that leaked toxins from previous activity will already have impacted the local environment and possibly its food chain.

Even if recycling was a simpler, more efficient process it is also worth noting that recycling can also be an inefficient process that results in carbon emissions of its own. Despite being less harmful than producing single use products this is something that is sometimes missed out of conversations that point to recycling as a solve-all solution. Innovation is taking place in the recycling sector, for example with the development of chemical recycling. This process changing the chemical structure of waste plastic, converting it into shorter molecules that can be re-used to make materials such as synthetic gas. While this process used less energy than mechanical recycling, the gas produced is still harmful to the planet and the process needs to take place near the site of virgin plastic production. This raises the question of whether we therefore need to be prepared to export used plastic back to where it came from, incurring more emissions from transport? It is clear that recycling is not a simple solution free from its own issues.

So why aren’t we using alternatives to plastic? It became clear as we continued to research that each material has its own unique set of advantages and disadvantages.

Paper Packaging

Paper is often seen as a greener alternative to plastic when it comes to packaging in the food and beverage industry. Many big brands are using paper and cardboard as a quick alternative to plastic following ambitious zero or reduced plastic claims. This is because paper is made from a natural, renewable resource and is the most recycled product in the world.

With marketing campaigns convincing us that paper is always better, it might surprise you to discover that a paper bag for example takes 3-4 times the amount of energy to make as its plastic counterpart. Ok, fine but it’s easier to recycle paper right? Wrong. The energy required to recycle paper is far greater than that needed to recycle plastic. It’s certainly better to use recycled paper – which used less energy than virgin paper to produce – but due to the pulping process that is needed for both processes recycling isn’t a quick fix. Pulping also uses a high volume of water, making paper production the most water-intensive industrial process (according to the WWF).

Recycled paper is also a better alternative to virgin paper as it does not rely on deforestation. According to Greenpeace, 4 billion trees per year are cut down to produce paper, making up 40% of the total use of industrial wood traded globally. This reduces the environment’s ability to absorb carbon dioxide and also leads to the destruction of habitats and exacerbates flooding risks. Despite being biodegradable, unlike most plastics, paper still comes at an environmental cost.

Let’s think about the material properties of paper for a moment. Plastic is lighter than paper which means a reduction of emissions in transportation. Paper and cardboard are also limited by not being easily compatible with drinks or wet foods. Even when we choose tetra packs in the supermarket it’s important to remember that these are lined with plastic to retain freshness and shelf-life.

Glass Packaging

Glass is often heralded as the zero-waste enthusiast’s dream as it can be recycled endlessly back to its original use. That means that a glass bottle can be recycled back into a glass bottle an infinite number of times without having to be permanently thrown away. If it sounds too good to be true, in that simplified explanation it is.

The major dangers of using glass come from its production. Its raw material is sand, which despite being naturally occurring on our beaches and deserts is being used up at a rate much faster than it can be made. Sand is collected from riverbeds and sea beds which raises the risk of flooding and soil erosion, leading to the displacement of wildlife and risk to the human population. As sand is scarce it is often mixed with soda ash and limestone.

The process requires all raw materials to be collected and transported to a batch house where they are sent to a furnace and heated at extremely high temperatures. Due to these high temperatures the furnaces often run on fossil fuels. Once the glassware is formed, it is transported elsewhere to be sterilised, then transported again for use as packaging. This means that there are a lot of emissions produced even before the packaged product itself is transported. Overall, this makes for a highly polluting process. The Global Warming Potential (GWP) of 1kg of glass is 1.25 million joules.

When thinking about glass as a material in the food and beverage industry you can quickly see why it is not commonly used. Glass breaks easily, leading to companies’ products being damaged in-transit. It is also very heavy, which raises freight costs and means more emissions produced during its transportation.

Glass Recycling

While the production process of glass is high-emissions, the recycling process is much less damaging. When glass is recycled it is broken down into smaller pieces called ‘cullet’, which can be re-melted at a lower temperature than the raw materials needed to make virgin glass. This reduces the emissions released by the process by 20% compared with glass production and decreases water use by 50%.

It’s worth noting though that not all glass ends up being recycled, for example only 33% in the US, and glass takes 1 million years to decompose naturally. While waste glass doesn’t release chemicals it is still damaging and Although not as harmful in some ways to the environment than plastic, it is not as clear cut as you may think. It seems that more needs to be done to ensure we minimise the amount of glass that is made from raw materials and maximise its recyclable properties.

Aluminium Packaging

One of the most re-used materials around, aluminium is a popular material in the food and beverage industry due to its ability to keep beverages cool, enhance shelf-life and hygiene and its light weight. It is also used widely in the cosmetics industry in products like deodorant.

Aluminium is made from a raw material called bauxite which rather than silver is soft and red. Bauxite is mined from the Earth in a labour-intensive process and is then processed into aluminium through a series of processes: first it is dissolved in sodium hydroxide then heated to very high temperatures before being combined with cryolite and extracted via electrolysis. This process uses a very high amount of energy, produces harmful gases and waste products and only yields about 1 tonne of aluminium oxide for every 4 tonnes of bauxite, meaning it isn’t a particularly efficient process either.

Despite the less-than-ideal production process though, aluminium can be recycled many times. In fact, almost 75% of aluminium ever produced in the US is still around today in one form or another. This makes it appealing despite its intense production process and dependence on finite natural resources. The energy needed to recycle aluminium is only 5% of that needed to produce it from scratch and produces only 5% of the greenhouse gas emissions. This makes recycled aluminium far preferable as a packaging material than aluminium made from raw materials.

Fabric Bags – An Alternative?

Fabric tote bags are a very popular packaging product that rose sharply in recent years as an alternative to plastic bags. They seem environmentally friendly as they can be used over and over again and have less risk of being disposed of. However, yet again, it is not as simple as it seems.

To manufacture a cotton tote bag takes a far greater amount of energy to make than a plastic bag. The amount is so great that you would have to use your cotton tote bag a staggering 393 times in order to match the environmental impact of using a plastic bag only 3 times.

If you’re looking to reduce plastic waste these bags can still be a positive alternative, but there are other factors to consider. There has been debate about organic cotton vs non-organic. Organic cotton is seen as better by many as it uses less harmful pesticides, but it also has a lower yield and therefore has a far higher water consumption. Here, as with many aspects of measuring environmental impact, it is not as simple as good vs bad – the materials perform differently in different categories of impact.

This is compounded by the fact that if you are looking at a tote bag vs a plastic one the plastic one comes out on top in terms of production – however, if you take waste pollution into account and ensure you re-use your tote then that would be your bag of choice.

Again, it is not as simple as it seems and it is clear that we still have a long way to go in our understanding of all the nuances of choosing appropriate materials.

Czarnikow’s Measures to Reduce Pollution

At Czarnikow, we’ve always tried to implement internal efficiencies to minimise our impact on the environment. However, as a company with operations running a dozen offices around the world, we have not always been able to reduce impact as much as we would have liked. At a time when we are moving into new ingredients markets including packaging, we have had to think once again about our role and responsibility in building a more sustainable future. That’s why we wanted to find out more about the various packaging options and share our findings with you.

Amidst the disheartening statistics of the harm we have already done to our planet, there is some hope. We know that if we work together, we can make a positive change. We need to move away from a linear plastics economy to a circular model where we are able to capture the positives of plastic while avoiding the negative impact it can have on the planet. This circular approach is where we’d like to be as a company and we will be talking about this in more detail in our next blog.