What Is Sugar?

A natural ingredient. The generic name that we give to this pure, sweet crystalline structure actually describes the group of compounds that provide living things – like you – with energy. While sugars naturally occur in what we eat, since discovering sugar around 8000 BC, humans have gladly welcomed sugar into their diets, now adding sugar to a vast amount of packaged foods from drinks to cereals.

1. The History of Sugar

2. How is Sugar Made

– Sugar Cane Production

– How is Beet Sugar Produced

3. Refined Sugar Production

4. Top Producers of Sugar

5. Quality Control Measures in Sugar

6. Sugar Cane Bagasse

7. Molasses

1. The History of Sugar

Before we started putting sugar in over 70% of the food in our supermarkets, sugar was known as ‘a powerful Indian medicine.’ Knowledge of sugar’s properties and techniques for its crystallisation was eventually consolidated by scholars at what is now the Iranian University, inadvertently giving Arab entrepreneurs the knowhow to produce and export sugar to North Africa and South Europe. Then in 1390 the new cane press instantly made mass producing sugar more efficient – a sensation for sugar obsessed-Europe. Fast forward to the 1500s with growing European colonisation: the tropical climate of the Americas is found to lend to impressive sugarcane yields. Eventually, European powers enslaved over 12 million Africans to work on sugarcane plantations throughout North, South and Central America. Meanwhile, a new plant that would change the sugar trade was being discovered back in in Europe. The abolition of slavery and transformative bioengineering exploits would mark the beginning of the sugar trade we know today.

You can find out more about the history of sugar in our blog that explores the evolution of sugar in more detail.

2. How is Sugar Made

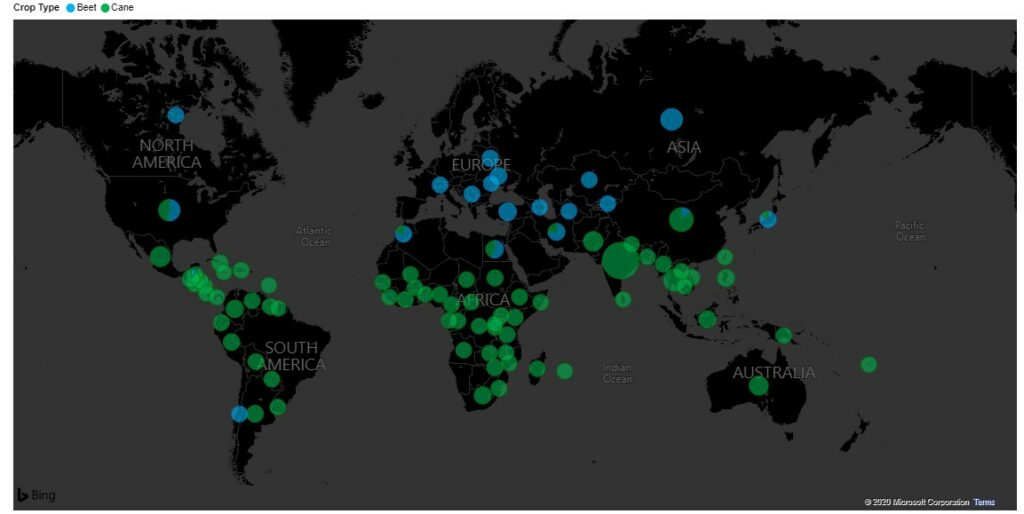

A common misconception is that all of the world’s sugar comes from sugar cane. Whilst sugarcane is responsible for nearly 80% of the world’s sugar supply, we need sugar beet in order to meet global demand yearly. Naturally the different biochemistries of cane and beet call for different extraction and processing techniques which we cover in the two blogs; Sugar Cane Production and How is Beet Sugar Produced.

– Sugar Cane Production

How sugarcane becomes the enticing stuff you find on supermarket shelves today has not changed much since the 12th century, when sugar refineries first popped up. If you’re wondering what exactly refined sugar is, it is sugar in its purest crystalline form containing at least 99.7% of sucrose – what you call ‘white sugar.’ Whilst the job of a sugar mill is to extract sucrose from cane or beet, a refinery’s purpose is to transform raw sugar into something fit for human consumption, characterised by a certain level of polarisation (don’t worry if you’re unfamiliar with this term because we explain it in the blog). There begins the nine-step process of refining sugar and we cover this further in our blog about the production of sugar cane.

– How Is Beet Sugar Produced

Unlike its counterpart, sugar beet is a root white, parsnip-like taproot plant that thrives in colder temperatures like those experienced in Northern Europe and Russia. Beet is popular among farmers because it is a rotation crop which means that it can be planted in the same plot as other crops to improve soil quality; it is usually a ‘break’ crop meaning it is planted between other crops’ rotations. It takes about a year from the time it’s sown for beet to be ready for harvesting. Before sucrose can be extracted from the plant by osmosis, the beet must be thoroughly washed upon arrival at the factory because it grows underground – a step that cane does not have. Find out more about beet sugar production in our blog that covers in more detail the process of farming, harvesting and processing of sugar beet.

3. Refined Sugar Production

How sugarcane becomes the enticing stuff you find on supermarket shelves today has not changed much since the 12th century, when sugar refineries first popped up. If you’re wondering what exactly refined sugar is, it is sugar in its purest crystalline form containing at least 99.7% of sucrose – what you call ‘white sugar.’ While a sugar mill’s job is to extract sucrose from cane or beet, a refinery’s purpose is to transform raw sugar into something fit for human consumption, characterised by a certain level of polarisation (don’t worry if you’re unfamiliar with this term because we explain it in the blog). There begins the nine-step process of refining sugar.

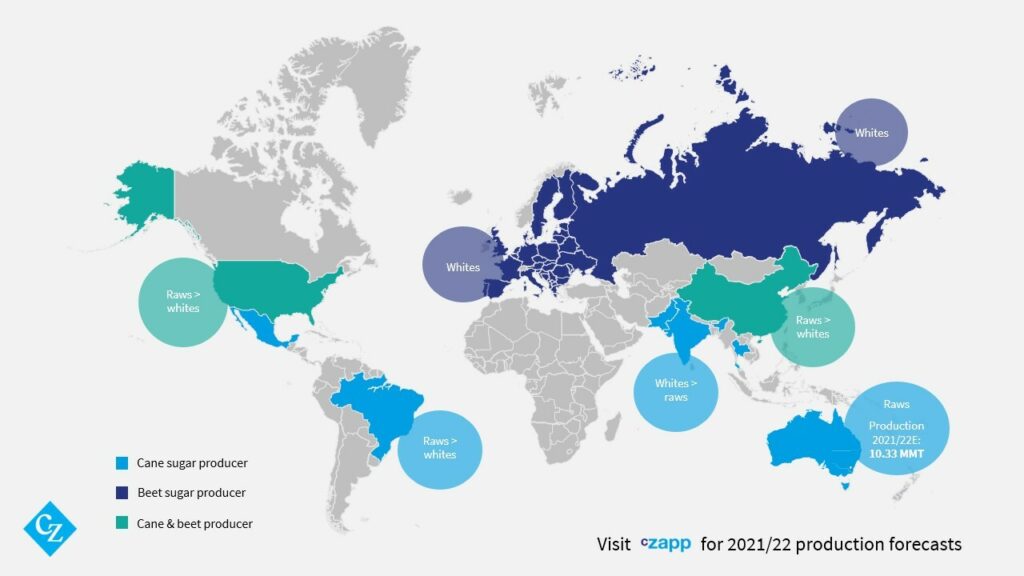

4. Top Sugar Producers

Where does most of the world’s sugar come from? How much sugar does the top sugar producer output year to year? Before you enter the market for a commodity you need to know where the supply comes from and which factors drive changes in production, exports and more – all of which you will find here in our ranking of the 2019/20 season’s top 10 sugar producers, as well as answers to some of the most frequently asked questions about the global sugar market.

5. Quality Control Measures in Sugar

Quality is of utmost importance in all commodity trading, and can impact the price, viability and legitimacy of a product. In the food and beverage industry, ‘quality’ means the combination of all attributes of a particular food item, for example appearance, flavour, nutritional content etc. There is an inherent chemical element to the determination of these attributes, and many food ingredients have particular values that must be met in order for them to meet the specifications of manufacturers. Each ingredient has its own language, with terms denoting different elements of the product that must be taken into consideration. For sugar the body that standardises its language is International Commission for Uniform Methods of Sugar Analysis (ICUMSA). In this blog you will learn how sugar is analysed and quality controlled; and get acquainted with the international system for classifying sugar.

6. Sugarcane Bagasse

Bagasse is the dry and pulpy residue is left behind when sugarcane stalks are crushed and is mainly used to manufacture paper but also doubles as a biofuel for generating electricity and heat energy. Although bagasse got its start in the paper industry, it’s becoming the preferred fuel for sugar mills because it utilises waste, reducing the mills’ energy costs whilst creating a closed production loop – one of the key practises of a circular economy. But what is it about bagasse that makes it so good at energy that it can meet the needs of a sugar mill? Read on in our blog about the history and origin, production, storage and sustainability of bagasse to find out more.

7. Molasses

the-sugar-series-what-is-molassesAlso known as the stuff that gives raw sugar that golden brown colour, molasses is an extremely versatile by-product of sugarcane and sugar beet having uses in baking, animal feed, brewing ale and distilling rum. If you’ve read our ‘Top 10 sugar producing countries’ entry, you can probably figure out where most of the world’s molasses come from. Molasses producers in the hot climates where cane thrives have the tricky job of keeping molasses below 45°C because it is highly temperature-sensitive and any more heat will cause foaming – imagine a pot of hot, viscous liquid bubbling over a hob but instead its truckloads worth – which risks losing product. As well as keeping a watchful eye on the temperature, producers must also consider the ‘brix’ in the molasses before trading it. Visit the entry to find out what brix is and how molasses is manufactured.