Dairy products are a recent addition to Czarnikow’s product portfolio. They were traditionally difficult to transport around the world, therefore limiting the geographies within which this commodity could be traded.

What Are Dairy Products?

Dairy products are any foods that are made from, and including, milk. Typically that will be milk, butter, cheese, cream, ice cream, yoghurt, dried milk powder and condensed milk.

By far the primary source of dairy is cow’s milk, and specifically from bovine species (comprising a diverse group of animals including cattle, bison, buffalo and antelope).

Fresh milk has been used extensively since the very beginning of time as a nutritious and sustainable food that is easily stored and consumed. Today more milk is produced and consumed than ever before. Much of the world’s milk is processed and manufactured into other products that are less volatile than milk, but in some countries roughly half the milk produced is consumed as fresh liquid with varying quantities of cream ie whole, skimmed or semi-skimmed milk.

In the early 1800s the typical dairy cow produced annually around 1,500 litres however this number is now much higher as a result of breeding techniques and nutrition with over 7,700 litres being produced by the average Freisian and some producing over 10,000 depending on the variety and how milk is supplied with different volumes of fat and protein.

Dairy Products: Packaging and Preserving

Today, there are more advanced methods of preserving, packaging and transporting dairy products, allowing for a more global movement of the various products in this category.

Dairy Products and Classification

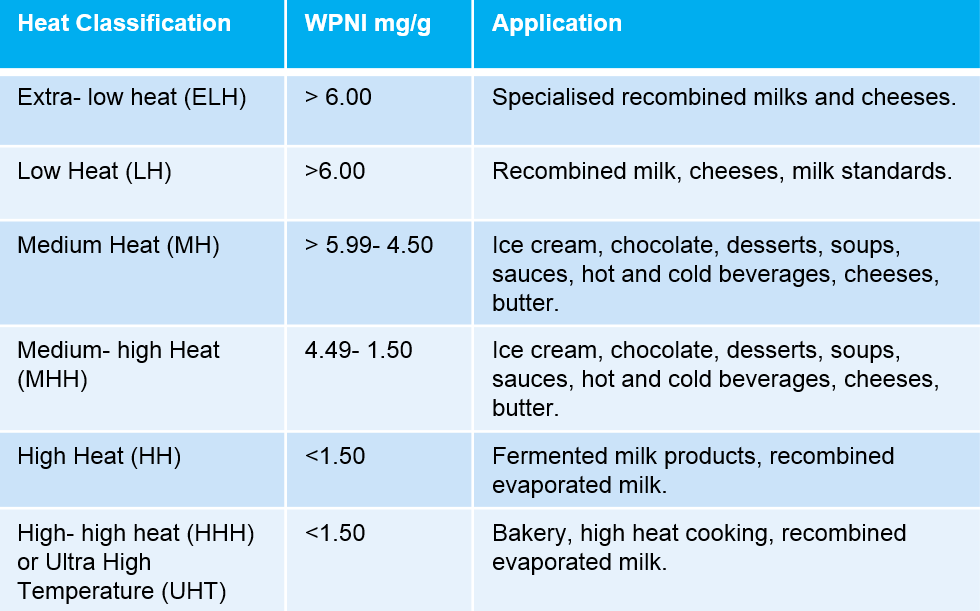

Milk powders are governed and categorised by their whey protein content, which is represented by a value we call Whey Protein Nitrogen Index (WPNI). Now here comes the snazzy bit…

Heat Classification

The Whey Protein Nitrogen Index, or WPNI, changes depending on what type of heat is applied to the milk during processing. There is a pattern in that low heat applications do not affect the WPNI as drastically as high heat applications. This means that low heat (LH) processed products tend to have a higher WPNI.

Here’s a useful table to show the relationship between heat and WPNI:

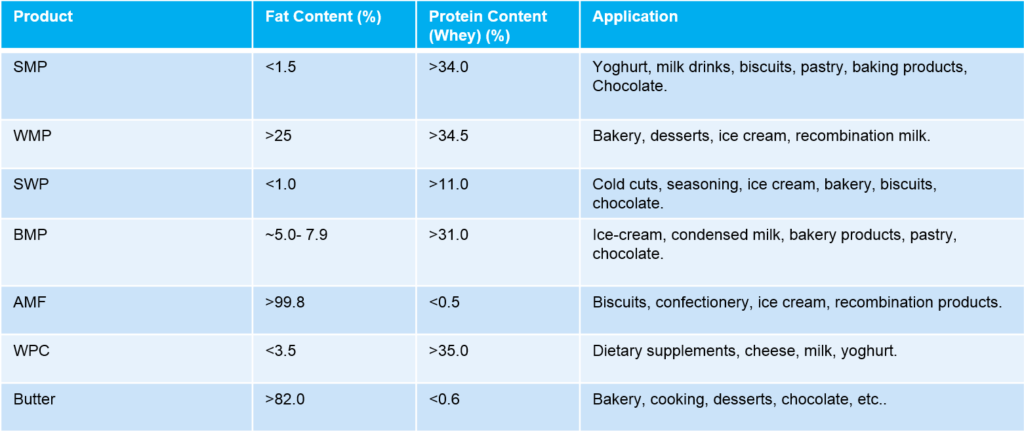

Dairy Products and Fat

So we know about heat. But there is another factor that we can’t ignore when talking about dairy: fat. Together, protein and fat are the composition components that give dairy products their value. Their value then determines the various applications that each product is more suited to. Here’s another chart to help:

It’s worth noting that Skimmed Milk Powder and Whole Milk Powder have the same WPNI because the differentiating factor (fat) is not affected by heat. WPNI in raw milk is determined by a number of additional factors, such as season, breed of cattle, feed and genetics.

Dairy Ingredients: Fun Facts

- A dairy cow has almost 360 degree vision

- One dairy cow creates four full time jobs in the local community

- A dairy cow has one stomach with four compartments

Whole Milk Powder (WMP) – also known as Full Cream Milk Powder (FCMP)

Fat content: >25%

Protein content: >34.5%

Typical sensory characteristics: white to cream, milky

Storage temperature: 30-45oC

Shelf life: 1 month after the loading date into bulk container. 6 months in big bags, 12 months in non-opened bags, 18 months in non-opened gas-flushed bags

Things to avoid: prolonged heat and light exposure, as this can lead to discolouration. Storing near intense odours can impact the product’s taste.

Key areas of supply for Czarnikow: France, Ireland, Germany & Oceania.

Whole Milk Powder: Origins and History

Milk powder is made by evaporating milk into a powdered form. This is done in order to preserve the dairy product and lengthen its shelf life, as in powdered form it does not need to be refrigerated. It retains a high nutritional value, making it a popular alternative to liquid milk across the world.

Milk powder has been on the market since the early nineteenth century, and is now made by the process of spray drying. Pasteurized milk is concentrated in an evaporator until it becomes approximately 50% solid. Then, it is sprayed into a heated chamber which evaporates the water and leaves the solid. Alternatively, milk powder can be made by the process of drum drying. In this procedure, milk is spread in a thin film to the surface of a heated drum. The water evaporates and the solids are scraped off the drum. The only problem arising with this second method is the milk powder can have a different, caramelized flavour. This is due to the contact with the heated drum. A popular alternative is also freeze drying.

Often used for: Bakery items, desserts, ice cream, recombination milk.

Skimmed Milk Powder (SMP)

Skimmed milk powder is manufactured in the same way as whole milk powder, but it has different properties. The WPNI varies depending on the heat class, with a higher heat resulting in a lower WPNI (following the pattern on the previous chart).

Fat content: typically >1.5%

Protein content: >34%

Typical sensory characteristics: white to cream, milky

Storage temperature: 30-45oC

Shelf life: 24 months in bags, 3 months after loading date in a bulk tanker.

Things to avoid: prolonged heat and light exposure, as this can lead to discolouration. Storing near intense odours can impact the product’s taste.

Key areas of supply for Czarnikow: The Netherlands, Belgium, Denmark, Indonesia, Poland, France, Ireland, Germany

Skimmed Milk powder: Origins and History

As we mentioned, skimmed milk powder undergoes a very similar process to whole milk powder. The difference between the two is the fat content, which is lower in skimmed milk powder. The milk is separated from the fat in advance of the drying process. Because of its lower fat content, skimmed milk powder has an even longer shelf life than whole milk powder. It’s lower fat content makes it a popular choice for products that aim to retain a lower fat content and be marketed as healthier options.

Often used for: Bakery items, desserts, ice cream, recombination milk.

Buttermilk Powder (BMP)

Buttermilk Powder is, unsurprisingly, made from buttermilk. Again, the clue is in the name as to how buttermilk is made – it’s made up of the liquid left behind after the churning of butter out of cultured cream.

Fat content: 5-7.9%

Protein content: >31%

Typical sensory characteristics: pale, yellow, milky

Storage temperature: 30-45oC

Shelf life: 1 month after loading date in a bulk tanker, 12 months in a non-opened bag.

Things to avoid: storage in high heat areas, high humidity areas or high odour environments. Avoid prolonged exposure to light.

Key areas of supply for Czarnikow: The Netherlands, Belgium, Denmark, France, Ireland, Germany.

Buttermilk Powder: Origins and History

Traditionally there was no easy method (homogenization if we’re being particular) available to easily separate a liquid into its various parts. What happened instead was milk being left to ‘sit’, allowing it to separate into cream and milk. The cream was turned into butter and the milk was used in other ways. During this process, the milk became fermented as lactic acid producing bacteria that naturally occur in milk began to break down the milk. In this state, the milk was easier to churn into butter, as the cream coalesces easier once it’s fermented somewhat. Buttermilk made in this way is still common in some geographies, particularly where it is hot. In Nepal, India and Pakistan it is very popular.

Cultured buttermilk is more common across the rest of the world. The end result is similar, but the cultures are put in artificially, rather than left to naturally occur. The milk is pasteurised, homogenised and then inoculated with live cultures.

Buttermilk powder is made in a similar way to whole milk powder and skimmed milk powder. It is concentrated and then dried, either by spraying or on a hot drum. It is a popular ingredient that has similar nutritional value to whole milk powder, but has a different taste.

Often used for: baked goods, cultured products, ice cream, confectionary, dressings and dips.

Anhydrous Milk Fat (AMF)

Anhydrous milk fat, despite its slightly unappealing name, is a very useful product. It is essentially butter with all water and non-fat dry matter taken out.

Fat content: >99%

Protein content: >0.5%

Typical sensory characteristics: pale, yellow, semi-solid, oily

Storage temperature: 10-14 degrees Celsius

Shelf life: 24 months in a drum at room temperature under gas, 12 months in a cardboard box at 1014 degrees, 15 days from manufacturing under neutral gas at 10 degrees above melting point.

Things to avoid: high heat, exposure to the atmosphere.

Key areas of supply for Czarnikow: The Netherlands, Denmark, France, Ireland, Germany.

Anhydrous Milk Fat: Origins and History

Because of its altered state, anhydrous milk fat can be transported more cheaply and preserved for far longer than ordinary butter. This makes it popular in hot climates, where it is often used for cooking, sometimes under the alternative name of ‘ghee’.

Anhydrous milk fat is made by melting butter at a high temperature, leaving the butter to rest and then nautralising the remaining product. One neutralisation has taken place to remove the fatty acids, sodium hydroxide, proteins and water are added before the product is passed through a centrifugal separator which concentrates the fat to above 99% and removes non-fat solids and most of the water. The anhydrous milk fat is then heated to 90-95 degrees and passed through a vacuum flash-vessel to remove more water and cool the product.

Considered a natural product, anhydrous milk fat has become a popular ingredient in baked goods, and now holds a market share as a raw material. However, there are also certain disadvantages. It has a high concentration of fatty acids, leading to health concerns. It is also expensive when compared with vegetable fats. It retains an advantage over vegetable products when it comes to flavour, allowing it to remain a popular choice across the food industry.

Often used for: baked goods, domestic cooking

Butter

This one is the most familiar of the list, but do you know all of these facts? Scientifically speaking, butter is a water-in-oil emulsion, with the milk proteins acting as the emulsifiers. It is made through the process of churning, which turns liquid milk into solid butter. The process contains many stages to separate the milk fat from the liquid and converting it into a solid.

Fat content: >80%

Protein content: <0.6%

Typical sensory characteristics: pale, yellow, solid.

Storage temperature: 0-5 degrees Celsius

Shelf life: At 0-5 degrees, maximum of 3 months after thawing or manufacturing, at -18 degrees, 24 months from manufacture.

Things to avoid: high heat and intense odour.

Key areas of supply for Czarnikow: Belgium, Denmark, France, Ireland, Germany.

Butter: Origins and History

Butter has been around for thousands of years. The earliest butter would in fact have been produced from goat or sheep’s milk, as the domestication of cattle was later than these other herd animals. Butter has been recorded in Greek and Roman texts where it was used for medicinal purposes, and we know of ancient methods of butter-making from Africa and the Near East. Ghee (which we may call anhydrous milk fat) is recorded in Indian Hindu literature that dates back as 1500 BCE.

If we’re talking about butter as we know it, this would have originated in the cooler climates of Northern Europe and Scandinavia where the product could be stored for longer without spoiling. In fact butter was so strongly associated with these regions that the Greek poet Anaxandrides referred to the ‘barbarians’ of the North as ‘butter-eaters’. For a time seen as the food of the peasants, butter gained popularity over the years. In the Victorian period, butter had become so in demand that Napoleon III was said to have offered prize money to anyone who could bring about a cheap substitute to add to France’s diminished butter stocks. In Ireland butter was so important that merchants founded a butter exchange in Cork.

It wasn’t until the mid-19th century that the production of butter became industrialised, meaning more butter could be produced at a much faster rate. Americans consumed a record-breaking amount of butter until World War II, when rationing made the cheaper alternative of margarine become more popular. Though health concerns made butter less popular in the late 20th century, it has lately staged a comeback as light has been shed on the potentially harmful synthetic additions to butter’s non-natural counterparts.

Often used for: baked goods, as a spread, in cooking.

Sweet Whey Powder (SMP)

Sweet Whey Powder is a concentrated and dried by-product of cheese or rennet casien production.

Fat content: <1%

Protein content: >11%

Typical sensory characteristics: off white to cream, powdered, fluid.

Storage temperature: 24-35 Degrees Celsius

Shelf life: 24 months.

Things to avoid: high heat and exposure to the atmosphere.

Key areas of supply for Czarnikow: Poland, France, Ireland, Germany.

Origins and History

Whey is the liquid that remains after milk has been curdled and strained as part of the cheese making process. More specifically, sweet whey is the liquid remaining after the manufacture of rennet types of hard cheese such as cheddar or Swiss cheese. Whey can be used to make certain types of cheeses, or as an additive in processed foods.

Sweet whey powder is made by drying fresh sweet whey. It contains all the same constituents as fresh whey except moisture, and its powdered form makes it easier to transport and store.

Often used for: condensed milk, recombined dairy products.

Whey Protein Concentrate (WPC)

Whey protein is protein derived from whey, the by-product of cheese production we’ve already looked at.

Fat content: <3.5%

Protein content: >35%

Typical sensory characteristics: off white to cream, powdered, neutral taste and odour.

Storage temperature: 24-35 Degrees Celsius

Shelf life: 12 months in an unopened bag.

Things to avoid: high heat and exposure to the atmosphere.

Key areas of supply for Czarnikow: Poland, France, Ireland, Germany, The Netherlands.

WPC: Origins and History

Whey protein is naturally present in cow’s milk, and can be extracted during the cheese making process. To make cheese, special enzymes are added to the milk to start the separation of curds and liquid whey. The liquid whey is then pasteurised and dried into a powder form. There are a few methods that could be used to do this, for example microfiltration and ion exchange.

Whey protein concentrate is the highest quality source of protein from a dairy product, and is available to the consumer as an ingredient or a supplement. Whey protein concentrate is particularly popular as it has a relatively low level of fat and cholesterol.

Often used for: Confectionary, baked goods, cereal bars, protein supplement products.

So that’s it for our current dairy product offering. You can find out more about our recent expansion into ingredients here at Czarnikow, and if you’d like to get in touch with a member of the team you can do so here.

Author: Carys Wright, Content Writer